Top 5 Signs Your Crusher Needs Servicing (And How to Avoid Downtime)

What We’ve Seen at ProTrack: Straight Stories from the Field

We’ve seen it all at ProTrack. From equipment so dry it almost squealed itself to death (although we did fix it up, of course), to crushers that cut out in mid-job because a bolt was left loose for too long. We don’t just sell and lease crushers—we fix them. And so, we’ve fixed more than our fair share of equipment that isn’t ours.

Too often, we get the call after the damage is done.

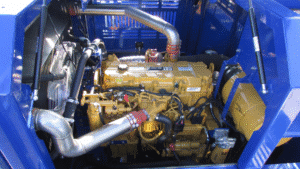

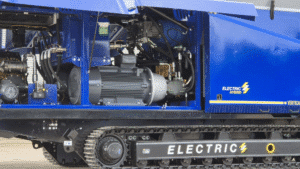

⬇️ Here we are, servicing an emergency at midnight on a Wednesday.

One customer called us distressed when their entire production line reached a standstill. When we arrived, their jaw crusher had locked up, with rock-solid bearings ripped, a motor burnt out, and a jammed feed that had been left for weeks. A simple vibration monitoring system and personnel training on warning signs would have prevented the $30,000+ downtime loss. We’ve now set them up with a maintenance schedule, predictive monitoring tools, and on-site operator training—and they haven’t missed a beat since.

One day, a crusher we were on was overheating every day and needed shutdowns that took an entire mining operation behind. No one had serviced the coolers or lubricated them in over a month. Our team cleaned the system, replaced filters, adjusted the feed rate, and added automatic warnings. Simple upkeep that had an enormous difference.

We do not share these stories to intimidate you—we share them because they are preventable.

That’s why every ProTrack customer doesn’t just get a machine; they get ongoing training, a tailored service plan, and service that keeps their business running at full speed. We allow our customers to catch the warning signs before they cause shutdowns. Even if your equipment isn’t ours, we treat it like it is—because uptime is everything in this business.

Crusher Servicing Sign 1: Unusual Sounds and Vibrations

- Loose or worn bearings

- Internal misalignment

- Debris build-up in the machine

- Overwear of the crushing chamber

- Carrying lubrication from time to time to avoid wear and tear.

- Periodic tightening of bolts and fasteners and inspection.

- Vibration analysis using predictive maintenance technology.

- Ensuring the crushing chamber remains free of any waste that would choke it.

Crusher Servicing Sign 2: Decline in Crushing Efficiency

- Tired jaw plates or liners affecting material breaking

- Clogging or blockage of material within the feed zone

- Hydraulic failure due to pressure shortage

- Improper settings leading to ineffective material handling

- Replace wear parts, including hammers and liners, regularly.

- Monitor feed size and material properties to avoid jamming.

- Check the hydraulic system for leakage and pressure.

- Adjust the crusher setting according to the material’s specifications.

Crusher Servicing Sign 3: Excessive Heat and Overheating

- Degraded or Lacking Lubricant

- Blind coolers or heat exchangers

- Excessive wear on moving parts

- Overloading of the motor due to overfeeding of material

- Maintain and change oil and lubricants periodically.

- Check the coolers and the fans frequently for blockage and accumulation of dust.

- Do not overcharge the crusher, and provide good material flow.

- Monitor temperature sensors and warn of excessive heat.

Crusher Servicing Sign 4: Increased Power Consumption

- Faulty motor parts or worn transmission belts

- Friction caused by inadequate lubrication

- Physical barriers are placing undue stress

- Deterioration of power transmission due to poor electrical connections

Crusher Maintenance Tips:

- Check the drive belts for wear and slippage.

- Lubricate all the moving parts.

- Remove material obstructions and ensure equal feed distribution.

- Check and maintain the electrical connections for efficient supply of electricity.

Crusher Servicing Sign 5: Leakage of Lubricants and Fluids

- Faulty hydraulic seals or gaskets

- Burst or leaking oil hoses

- Cooling system leaks

- Over-charging or under-servicing lubrication systems

- Check the hoses and seals regularly for wear and replace them whenever necessary.

- Check fluid levels while performing the daily maintenance routine.

- Check the hydraulic system pressure for sluggish leaks in advance.

- Employ top–quality lubricants that are up to manufacturer standards.

Early leak fixing prevents complete breakage, minimizes the possibility of contaminants, and makes the machine long-lasting.

5 Ways to Avoid Your Crusher Shutting Down

1. Practice Preventive Crusher Maintenance Schedule

- Do daily, weekly, and monthly inspections.

- Follow the supplier & manufacturer’s maintenance guidelines.

- Monitor the performance with condition monitoring software.

2. Practice Crusher Operator Training

- Train staff in the earliest stages before signs of failure.

- Train staff on proper feeding and loading practices.

- Encourage frequent reporting of abnormal noise or loss of performance.

3. Use Proper Spare Parts

- With Original Equipment Manufacturer (OEM) parts.

- Avoid low-cost, low-quality parts that cause further breakages.

4. Invest in Predictive Maintenance Technology

- Use thermal imaging, vibration analysis, and oil sampling to find issues early on.

- Utilise automatic monitoring systems for real-time machine health monitoring.

5. Prepare Spare Parts & Solutions

- Hold spares such as bearings, belts, and filters in inventories.

- Schedule periodic replacements to avoid extended periods of downtime.

Having your crusher serviced regularly will prevent costly breakages, maximize equipment longevity, and sustain productivity.

Wrapping up

At ProTrack, we realise the importance of your crusher to your business. Being a Canadian seller, renter, and servicer of heavy equipment, including crusher equipment, we sell the machinery, but not just that—we support it with skilled service, maintenance, and support. From scheduled wear and tear to scheduled downtime, our factory-certified technicians and field service work get your equipment running less, with more equipment life to show for it.

Why choose ProTrack for Crushing Equipment and Servicing?

- Full Service Support: From inspection and breakdown repair to complete overhaul.

- Parts in Inventory: OEM and performance aftermarket parts in inventory and available to ship.

- Flexible Rental & Purchase Options: Stay operational while your crusher is down for repairs.

- Expertise: Our staff help you design a preventive maintenance plan for your crushing business uniquely suited to your situation.

Don‘t wait for a breakdown. Call ProTrack today to book a crusher inspection or learn more about our maintenance and servicing packages built to minimize downtime and optimise your productivity.

FAQs Crusher Maintenance

- How frequently should I service my crusher?

Routine maintenance must be performed every 500-1,000 hours, depending on the application. Periodic lubrication and inspection are still suggested. - What is the most common cause of crusher failure?

Poor maintenance and inadequate lubrication are the root causes of failure, which result in overheating, wear, and failure of parts. - Can I perform maintenance on my crusher?

Simple internal maintenance, like lubrication and inspections, can be performed, but skilled mechanics must do intricate repairs. - What would make my crusher over-vibrate?

Excessive vibration may result from loose parts, worn bearings, or poor rotor balancing. - What will happen if my crusher is not serviced?

Neglecting to keep your crusher in top condition may result in unforeseen breakages, costly repairs, and even long-term equipment destruction.