10 Crushing Equipment Issues & Solutions

10 Crushing Equipment Issues & Smart Solutions That Save You Thousands

Portable crushers and screeners are powerful machines in the heavy equipment industry today. From road construction, aggregate production, to demolition work, these pieces of equipment gnaw away at materials like a knife through warm butter. However, even the strongest crushing equipment has the potential to experience crushing equipment issues.

When that happens, you’re not just facing downtime—you’re facing late schedules, lost business, and even safety issues. With ProTrack, we rent and sell high-end mobile crushers and screeners and build a rock-solid reputation for quality service and repairs. In this article, we lift the lid on the 10 most common crushing equipment issues, and more importantly, how to fix them quickly.

Crusher Not Working?

Here’s 10 Crushing Equipment Issues to Explain Why:

1. Why Won’t a Crusher Start?

You hit the start button, and nothing happens. The silence is deafening. The issue is probably simple, but it can cause major delays:

- Dead battery: Idle crushers may drain batteries.

- Tripped breaker or blown fuse: Quick to replace, but easy to overlook.

- Engaged emergency stop: A hard-to-spot red button could be the culprit.

- Worn starter motor: It happens more often than you think.

Fix it: Start with the basics—test all breakers, fuses, and emergency stop circuit. Clean your terminals and make sure your voltage output is to spec. Call ProTrack if needed—our heavy equipment techs are just a call away.

2. Jaw Plate Wear: More Than Just a Surface Issue

Jaw plates are under great pressure when the machine is working. Asymmetric wear can lead to:

- Lower crushing efficiency

- Inconsistent flow of materials

- Unwanted product size

Repair it: Periodically rotate or reverse jaw plates. Make sure that the feeder is feeding the material evenly. Take advantage of ProTrack’s inspection service and schedule off-hour liner inspection.

3. Excessive Vibration? Your Machine Is Telling You Something

Another crushing equipment issue is vibration; it’s not just annoying—it’s an early warning signal. It can ruin bearings, bend frames, or lose vital parts if not addressed.

Common causes:

- Worn or out-of-balance rotor

- Loose flywheel or bolts

- Foundation cracks

Fix it: Turn off the machine immediately. Inspect rotating equipment. Use vibration analysis to detect imbalances.

4. Clogged Crushing Chamber: A Productivity Killer

When material clogs the crushing chamber, you’re at a standstill. It’s annoying and hazardous.

Why is your crusher clogging:

- Overfeeding sticky material

- Worn-out liners are taking up chamber space

- Wet material sticking and bridging

Repair it: Employ built-in clearing mechanisms or reverse feeds. Never enter the chamber without complete lock-out/tag-out. Need assistance clearing a blocked machine quickly? ProTrack’s emergency support team is always available.

5. Conveyor Belt Failures: Keep the Material Moving

The next crushing equipment issue is that your conveyors are the heart of crushing operations. When they fail, so does everything else.

Common crushing equipment issues with conveyor problems:

- Belt misalignment

- Torn or frayed edges

- Jammed pulleys from debris

Fix it: Regular alignment checks. Replace worn belts. Clean around the tail and drive pulleys.

6. Hydraulic Headaches: Don’t Ignore the Warning Drips

Hydraulic malfunctions or system leaks cause unpredictable performance and downtime. Don’t wait until your crusher runs “sluggish.”

What to Watch for with Crushing Equipment Issues With Hydraulics:

- Dirty or foamy fluid

- Weak cylinder actuation

- Blown hoses or seals

How to Fix Crusher Hydraulic Issues

Replace hydraulic filters, flush contaminated oil, and check system pressures.

7. Overheating Engines: The Stealing Efficiency Culprit

A common crushing equipment issue is overheated engines that lose power, use oil, and cut machine life.

Common crusher overheating:

- Clogged radiators

- Bad fans or belts

- Low coolant levels or faulty sensors

How to Fix an Overheating Crusher:

Check the quality of the coolant. Clean all cooling fans and fins. Replace defective thermostats or fan motors.

At ProTrack we carry the best-selling parts of most major mobile crusher brands in stock.

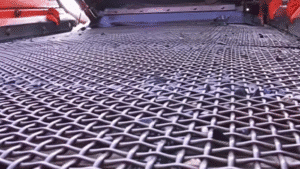

8. Screeners Not Properly Separating Material?

If your output quality dips, your screener might be to blame.

Watch for:

- Torn mesh

- Improper screen angle

- Overloading

How to Fix Improper Screener Separation:

- Replace worn decks.

- Adjust the angle and vibration frequency.

- Don’t forget to calibrate the feed rate.

9. Bearings Failing Too Soon? Here’s What You’re Missing

A big crusher equipment issue that can be overlooked is that bad bearings are catastrophic, but the truth is, they’re preventable.

Why heavy equipment bearings fail:

- Incorrect or improper lubrication

- Misaligned shafts

- Housing contaminants

How to Repair Failed Bearings on Heavy Equipment:

- Use high-quality grease or oil as specified by the manufacturer.

- Keep dirt and moisture out.

ProTrack offers precision bearing installation and alignment—a requirement to avoid premature failure.

10. Bad Output Size Control? It’s Not Always the Material’s Fault

If your product size is not consistent, don’t blame the rock.

Most common problems:

- Incorrect crusher settings

- Worn jaw or cone liners

- Misaligned CSS (closed side setting)

How to Repair Bad Output on a Crusher or Screener:

- Check your CSS regularly and check the wear part thickness.

- Replace or flip liners before they get too far along.

ProTrack BC stocks wear parts and offers same-day changeout service.

Need Heavy Equipment Servicing Near You?

ProTrack Has You Covered

Here’s the truth about crushing equipment issues: equipment breaks down. What you do about them, though, matters. That’s where ProTrack comes in.

- Sales: We carry top-tier mobile crushers, screeners and more from exclusive reputable suppliers.

- Rentals: Portable short or long-term applications, backed by maintenance protection.

- Service: Emergency repairs, regular maintenance, rebuilds—in-shop or on-site.

- Support: Technical assistance, operator training, and part procurement by our qualified personnel.

Whether it’s an easy belt fix or full hydraulic rebuild, ProTrack is your single-source answer to crushing equipment uptime. Need help right away? Contact us now.

FAQs

- What’s the most common crusher issue?

Electrical and startup issues lead the list, especially in seasonal applications. - How can I tell if my screen needs to be replaced?

The most blatant indicators are uneven particle size, lower throughput, or seen tears. - Does ProTrack offer emergency assistance?

Yes! We have 24/7 mobile repair services in British Columbia. - What kind of crushers does ProTrack rent or sell?

From jaw crushers to impact crushers and screeners—rock, asphalt, or demolition recycling equipment and more.

Conclusion: Don’t Let Downtime Crush Your Goals

Crushers are the muscle of any serious material handling project. But such a steady workhorse demands the same consideration, attention to detail, and encouragement as any loyal machine. And by knowing what these usual worries are—and with a good service partner like ProTrack behind you—you can keep those rocks rolling, your operators safe, and your project deadline in place.