What Is the Difference Between VSI Crusher and HSI Crusher?

VSI vs HSI Crusher: Top 2025 Guide to Choosing the Best Impact Crusher Machine

It is essential to know the difference between VSI crusher and HSI crusher for anyone who is operating within the sector of crushing equipment. Regardless of whether you’re buying a VSI crusher for sale, valuing a used VSI crusher for sale, or looking at an HSI impact crusher, knowing key differences and comparison of the VSI vs HSI crusher will enable you to make the right choice for your business.

Impact Crushers: Vertical Shaft and Horizontal Shaft

Impact crushers are a leading class of crusher machine utilized in the crushing of rocks, concrete crusher plants, mobile crusher machinery, and stone crusher equipment. Instead of compressing material as a jaw crusher, cone crusher, or a rock crusher, impact crushers utilize force to break it. Two broad categories exist, which include our VSI vs HSI crusher:

- Vertical Shaft Impactor (VSI crusher) – also referred to as vertical shaft impact crusher or vertical shaft crusher.

- Horizontal Shaft Impactor (HSI crusher or HSI stone crusher, HSI crusher machine).

It’s a summary of their differences, key equipment, and how each relates to crushing equipment setups, whether you’re buying a crusher machine or supplementing a stone crusher plant.

What is a VSI Crusher? (Vertical Shaft Impactor)

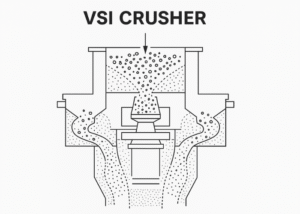

A VSI crusher operates at high velocity to crush material. The feed is given in the centre of a rotating rotor and is launched outward at velocities of up to 70 m/s against the walls of the chamber, which is formed by centrifugal force.

Such operation produces well-graded, cubical product and manufactured sand and is suitable for application in the tertiary stage crushing.

Top VSI Equipment Examples:

1. EDGE Innovative VS420 (Electric/Hybrid)

- Combines electric and diesel power, best suited for indoor/outdoor use. Lessens CO₂ emissions and operating costs. Producers cubic aggregates and high-grade manufactured sand.

2. Auspactor VSI by H-E Parts

- Heavy-duty design, reversible anvils, and high-wear resistance—best suited for abrasive feed and longer service life.

Used VSI Crusher for Sale

Portable industrial VSI machinery available. Best suited for mining or sand manufacturing.

If you are looking for a VSI crusher for sale or a vertical shaft impact crusher for sale, check out ProTrack’s selection here for can provide new and used models to meet your business needs.

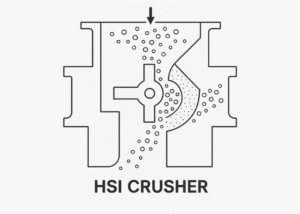

What Is an HSI Crusher? (Horizontal Shaft Impactor)

HSI, or Horizontal Shaft Impactor, operates differently. Material is fed in at the top and struck by blow bars mounted on a turning rotor. It’s then thrown against impact plates, where it breaks on impact.

Such an arrangement is appropriate for larger feed sizes and harder materials, and therefore, HSI crushers are the choice of primary crushing applications of limestone, concrete recycling, and asphalt.

HSI Equipment of the Examples:

1. Terex Finlay I‑120RS HSI Crusher

- Mobile HSI impact crusher with direct-drive CR038 chamber, high throughput, consistent shape, and integrated screening—ideal for quarry, recycling, demolition, and mining.

2. Terex Finlay I‑140RS Impact Crusher

- Mobile crusher with CR032 chamber, hydraulic apron close, screen removable, and T-Link telematics—high-capacity application specialist.

VSI vs HSI Crusher: Key Design Differences, Application, and Performance

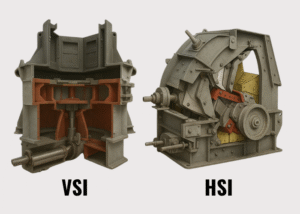

Crusher Design & Crushing Mechanism

The primary distinction between a VSI crusher (Vertical Shaft Impactor) and an HSI crusher (Horizontal Shaft Impactor) is in their motion and impact approach. VSI crushers use vertical speed to hit rock on rock or metal, creating sharp, angular fragments. HSI crushers rely on horizontal blow bars striking the material and throwing it against impact plates for reduction.

- VSI = Shape + Speed

- HSI = Volume + Impact

This early difference shapes their preferred usage—VSI crushers are designed for precision and finish, while HSI crushers are designed for raw bulk and mass reduction.

VSI vs HSI Crusher Applications, Efficiency & Suitability

When used in a crushing circuit, VSI crushers work optimally for tertiary or final crushing, mainly when producing manufactured sand or crushed products with good shape. HSI crushers, on the other hand, work optimally for primary and secondary crushing and work well breaking hard materials like concrete, demolition waste, and asphalt.

VSI units function well on medium-hard, non-abrasive rock like limestone and sandstone, with improved energy-to-output ratios for fine crushing. HSIs are naturally better suited for bulk reduction with larger feed sizes, although they will wear more aggressively when crushing abrasive material.

VSI vs HSI Crusher Performance, Maintenance & Operational Flexibility

VSI crushers tend to operate at higher speeds (up to 1800 RPM), which allows them to better size the particles. They also offer flexibility in the form of rotor speed control, chamber design, and feed setup—ideal for dial-in control of gradation output.

HSI equipment has fewer RPM but greater impact force, which is equivalent to greater throughput. HSI equipment is easier to maintain and repair since blow plates and bars are easily accessible, though they have a quicker wear life, especially when crushing abrasive material.

VSI crushers require more cautious maintenance—rotors, anvils, and bearings require meticulous attention—but softer materials wear less, and rock-on-rock configurations significantly reduce part deterioration.

VSI vs HSI Crusher Cost, Environmental Impact & Innovation

In the average market VSI crushers tend to be more expensive initially as they have more complicated internals. Yet, where particle shape and surface texture are a consideration, they cut downstream expense through improved product quality.

HSI crushers are typically less expensive to purchase upfront, thus being well-suited for high-volume installations with less focus on precise particle shape. But constant replacement of parts—particularly blow bars—can increase operating expenses over the years.

Environmentally, VSI crushers are quieter and cleaner, especially in urban or indoor settings. HSI units, owing to their forceful crushing action, can be noisier and dirtier unless properly installed.

Both technologies improve:

- VSI improvements: Smart feedback systems, auto-lube configurations, and improved rotor balancing.

- HSI improvements: Self-compensating breaker plates, variable speed drive, and smart wear monitoring.

VSI vs HSI Crusher Efficiency, Cost & Maintenance

- Efficiency: VSI equipment is economical in terms of energy when it comes to fine shaping; HSI crushers are optimized for bulk volume and feed size.

- Cost: For sale VSI crushers are of high initial cost and maintenance; they, however, outperform in low-wear applications. HSI units are inexpensive but require frequent replacement of blow bars while maintaining abrasive material crushing.

- Maintenance: VSI machines demand very careful maintenance of rotor and anvils; HSI blow bars and impact plates are easier and replace when needed.

Which Crusher Should You Use?

Wrapping Things Up

Choosing between a VSI crusher plant and an HSI crusher—or between a cone crusher, jaw crusher, or used concrete crusher—comes down to material type, product shape requirement, and rate of production requirements. VSI crushers are best for precision and control of shape; HSI crushers are best for volume and heavy usage.

Have Questions or need advice?

ProTrack offers expert support to acquire the right crushing machinery—from HSI impact crusher and mobile crusher to VSI crusher for sale or used VSI crusher for sale. Contact ProTrack today and let our personnel help your crushing project from equipment selection to installation.

Schedule a free equipment consultation or check out our available crushers at protrackequipment.com

Contact ProTrack now or call 778-900-4595 and let our team guide your crushing project from selection and delivery to maintenance and training.

FAQs – Crusher Equipment

What is the most significant difference between HSI and VSI crusher?

- HSI uses horizontal impact blow bars; VSI uses vertical centrifugal speed in shaping material.

Which one is best suited for manufactured sand?

- A perfect VSI crusher because of its ability to produce cubical particles.

Are HSI crushers suitable for concrete recycling?

- Completely—HSI impact crushers easily break reinforced concrete and asphalt.

Is a VSI crusher more expensive?

- Yes, upfront, but they are economical on wear expenses in the long term with the right materials.

May I use both VSI and HSI at the same time?

- Yes—HSI for preliminary crushing, VSI for final shaping is a very standard, efficient combination.

Do you have any used VSI crusher for sale from ProTrack?

- Yes—we always list certified used VSI crushers besides new and mobile ones.